01 October, 2021

01 October, 2021DOIMAK, a high-technology grinding machine manufacturer since 1974, will participate in the EMO Milano 2021 trade show (Hall 1, Stand C32) to introduce its new generation of 6-axes grinding machines.

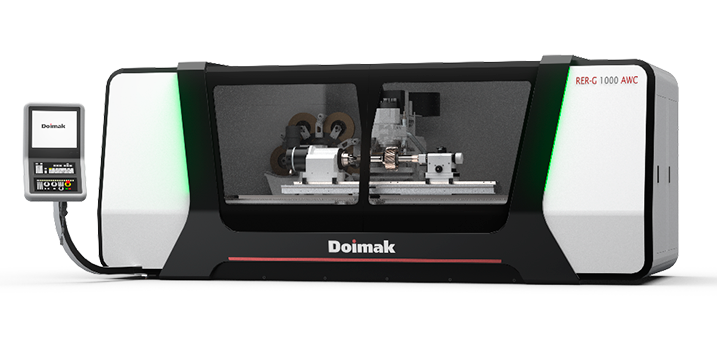

DOIMAK will demonstrate its new RER-G 1000 AWC design, a multi-operational machining centre with an automatic grinding wheel loading system and integrated measuring system. This innovative design also features a rotary head (B axis) that enables grinding of a wide variety of workpieces.

The solutions integrated in the machine make it agile, independent and fast.

The 6-position wheel magazine is capable of storing a wide range of wheels with diameters from 40 to 350 mm. The magazine features an independent access for simple and safe user operation.

Automatic wheel loading is carried out by a robust HSK-E system that also changes the cooling nozzle.

As a whole, the system provides the versatility needed to perform multiple operations and guarantee repeatability in changes and transitions.

Another of the significant new features in the machine is the gear measurement system. Not only does the new system offer an automatic positioning function, but it is also capable of measuring the three most important properties of the gears (profile line, edge line and step). This has been achieved by developing a specific graphics viewing software with the main goal of taking it one step further to measure, display results and make corrections in the machine itself.

In sum, the design of the new RER-G 1000 AWC is compact and versatile, intended to improve multi-operation processes by including new technological advances required by the most demanding manufacturing processes.

DOIMAK, a high-technology grinding machine manufacturer since 1974, will participate in the EMO Milano 2021 trade show (Hall 1, Stand C32) to introduce its new generation of 6-axes grinding machines.

DOIMAK will demonstrate its new RER-G 1000 AWC design, a multi-operational machining centre with an automatic grinding wheel loading system and integrated measuring system. This innovative design also features a rotary head (B axis) that enables grinding of a wide variety of workpieces.

The solutions integrated in the machine make it agile, independent and fast.

The 6-position wheel magazine is capable of storing a wide range of wheels with diameters from 40 to 350 mm. The magazine features an independent access for simple and safe user operation.

Automatic wheel loading is carried out by a robust HSK-E system that also changes the cooling nozzle.

As a whole, the system provides the versatility needed to perform multiple operations and guarantee repeatability in changes and transitions.

Another of the significant new features in the machine is the gear measurement system. Not only does the new system offer an automatic positioning function, but it is also capable of measuring the three most important properties of the gears (profile line, edge line and step). This has been achieved by developing a specific graphics viewing software with the main goal of taking it one step further to measure, display results and make corrections in the machine itself.

In sum, the design of the new RER-G 1000 AWC is compact and versatile, intended to improve multi-operation processes by including new technological advances required by the most demanding manufacturing processes.

Subscribe to our newsletter. Just insert your e-mail and you will receive the latest news.