06 September, 2017

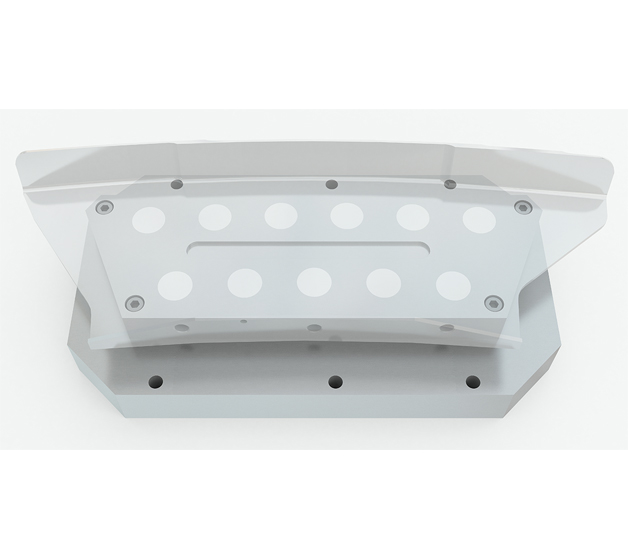

06 September, 2017T-GRIP is an adhesive clamping material and a family of clamping components capable to develop higher clamping and adhesion forces than any other alternative technology in the market, on any rigid material kind (ferromagnetic, non-ferromagnetic, composite…). Used to build fixtures and clamping devices for work-piece manufacturing purposes, allows the fixation of the piece with lower interference with machining and shaping tools than any other alternative technology in the market. This leads to significant reductions in the number of different working steps needed to be executed in the manufacturing of complex pieces and requiring lower amount of different fixtures to manufacture the pieces along the process. In overall, T-GRIP is capable to reduce by 50% the total cost of workpiece holding during production of complex pieces.

T-GRIP PROJECT:

T-GRIP is a revolutionary solution for the machining of complex high-value workpieces, such as:

- Large pieces with complex geometries, requiring several consecutive clamping-machining operations and several workholding fixtures.

- Pieces in advanced materials, particularly non-ferromagnetic ones like aluminium, titanium and composites.

Complex high-value pieces are a growing field, particularly in high requirement sectors like the aeronautic. Remarkable examples of these pieces are fuselage structures and complex pieces of the jet engines.

FRESMAK, in collaboration with POLYMAT –UPV University-, has developed an alternative innovative clamping element, T-GRIP, based on the principle of adhesion. Main features of T-GRIP are:

- It’s a rigid, non-residue leaving, reversible and reusable adhesive material activated and deactivated through temperature (>60⁰C) that maintains adhesion force at ambient temperature.

- Easy to manufacture, cheap material that can be machined at precisions below 0,003 mm, to create high precision fixture-workpiece contacts and unions.

- Does not compromise the cutting area.

- Very high adhesion, clamping and cutting forces per unit of surface (1.100 N/cm2).

This principle is applicable both to ferromagnetic and non-ferromagnetic materials, and is suitable for thin wall and complex geometries. At the same union force range it is 50% cheaper than the vacuum alternative and 80% cheaper than the electromagnetic solution. At a same range, pieces of high complexity, thanks to T-GRIP require less fixture equipment and machining steps, which is 70% cheaper than the mechanical clamping systems.

The main Customer Value Propositions are:

- Average price reduction rate compared to the closest competing technology in biddings.

- Average clamping time ratio reduction compared to the closest competing technology.

DESIGN AND MANUFACTURING OF WORKHOLDING FIXTURES

FRESMAK is specialized in the design, development and manufacturing of workpiece holding and clamping solutions for the manufacturing of complex pieces. FRESMAK has a deep knowledge in the field of piece holding and clamping, particularly for particularly complex workpieces, that make to the process designers and workshops more cost effective and profitable to hire its services and purchase its tailor-made fixtures than to design and build their own ones.

Subscribe to our newsletter. Just insert your e-mail and you will receive the latest news.