28 March, 2023

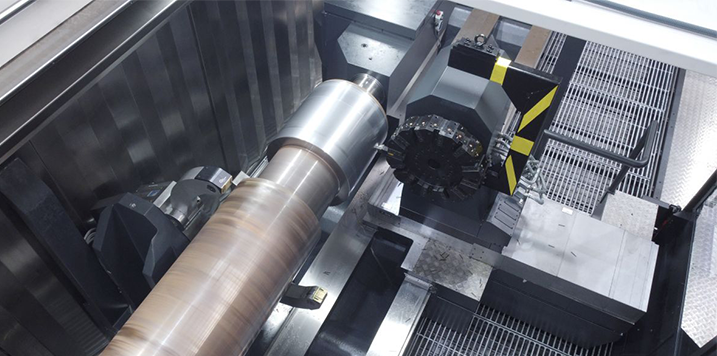

28 March, 2023The solution developed in the ROTVI project increases efficiency by eliminating chip buildup on the cutting tool during machining. This technology is the result of the developments and research that GEMINIS applies to the design of its lathes, aiming to create the easiest-to-clean lathes and the best solutions for chip and coolant evacuation and management.

Cutting-edge technology that improves precision and productivity

The ROTVI project is an innovative technological solution that improves efficiency, precision, and productivity during machining processes. It achieves this by generating shorter chips that prevent blockages in the evacuation, allowing for the automation of the machining process.

At GEMINIS, they also believe that this optimized system results in lathes that are easier to clean, which leads to safer lathes. Among the elements of the evacuation and management system that they have been including in their lathes, the chip conveyor stands out, responsible for evacuating and transporting them to a container or filtration system.

Regarding the chip channeling process, their lathes have a bed and frontal and chuck protections to facilitate evacuation.

Their equipment also has total protection: they are made of stainless steel, and there is the possibility of integral shielding that provides greater sealing and safety.

Another case of public-private collaboration

This ROTVI project is an innovative solution from GEMINIS funded by the Basque Government and the European Union through the Hazitek program, co-financed by the European Regional Development Fund (ERDF).

This is not the first case of collaboration between GEMINIS and public institutions. Discover the case of the GR3-W HP project, for the development of a cutting-edge boring machine in the railway sector.

Subscribe to our newsletter. Just insert your e-mail and you will receive the latest news.