23 May, 2019

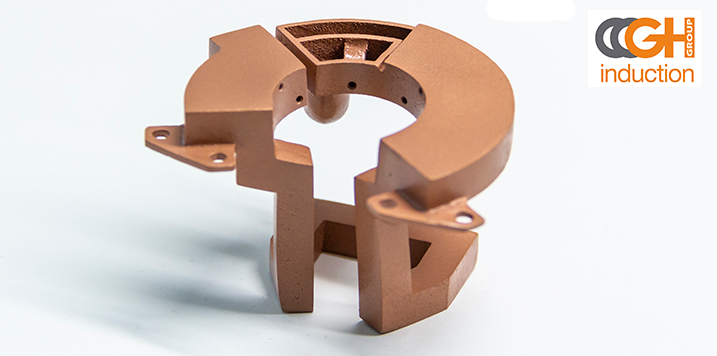

23 May, 2019GH INDUCTION group launches its new website www.3dinductors.com to spread its exclusive technology of 3D printed coils / inductors made of pure copper of which GH is the pioneer worldwide.

This coil additive manufacturing technique is a breakthrough in the history of industrial induction heating technology that is already being deployed in automotive and industrial companies for the great benefits it provides.

Inductors are a critical part in induction heat treatment. They must be replaced from time to time due to natural deterioration, causing interruption to production and consuming many man-hours for process re-verification.

With GH's 3D inductors, the service life of the inductors is increased in an extraordinary way (there are cases up to 4 times longer), the coil spares are geometrically identical, and the designs are optimized for the most efficient performance. This means reduced production costs per part and an improvement in treatment that cannot be achieved with current technology.

The technology is based on Electron Beam Melting (EBM), the only method today that works with pure copper rather than alloys, giving greater current carrying capability to the inductor, improving efficiency and extending inductor life.

GH INDUCTION is an international group specialized in electromagnetic induction heating of metals. It offers solutions for all industrial sectors for heat treatments (quenching, tempering, etc.), welding, assembly, straightening, etc. with GKN, Audi, Robert Bosch, Sandvik, Vicinay, Prysmian, ABB and General Electric among its customers.

Subscribe to our newsletter. Just insert your e-mail and you will receive the latest news.