03 June, 2022

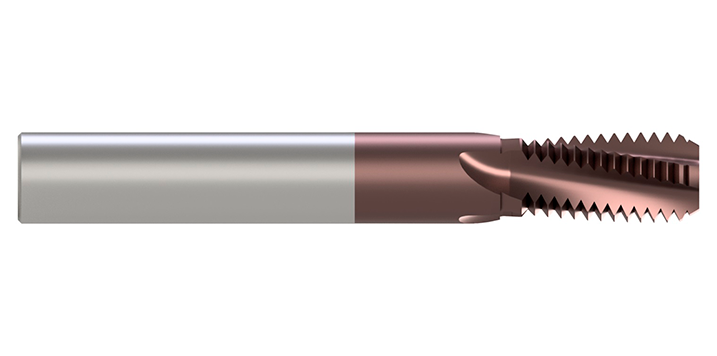

03 June, 2022HEPYC incorporates interpolation thread milling cutters in its 2022-2024 catalogue. With this tool, threading and deburring is carried out in a single operation on very hard materials.

They are milling cutters made of Integral Hard Metal (HM-MD) and with a multilayer coating of TiAlCN (Titanium-Aluminum Carbonitride) that allows it to reach maximum temperatures of 500ºC, with a Vickers hardness (HV) of 3,800, a coefficient of friction of 0.4. They are manufactured with a 15º geometry, a characteristic that gives them a lower probability of breakage during the machining process itself.

These interpolation thread milling cutters are suitable for threading practically all types of materials, although they are ideal for materials above 50 HRC.

The advantages of using this type of tool can be summarized in 3 points:

They have a range in M from M2*0.40 to M24*3.00 and in GAS they have a range from G1/16-1/8 to G≥ 1”

In addition, HEPYC has a program that makes it easy to choose the right tool.

The entire HEPYC range at: https://www.hepyc.com/es/Thread-taps/Hard-metal-thread-mills/subfamily-54

Subscribe to our newsletter. Just insert your e-mail and you will receive the latest news.