23 October, 2023

23 October, 2023Ibarmia Innovatek's innovative journey has gained momentum in the year it commemorates its 70th anniversary of establishment. The company will exceed three million euros in investment across six Hazitek 2023 projects in which it participates: four strategic projects (Accubask, Maqhia, Upscale, Conflex) and two competitive projects (Saturno and Orkestra), in addition to an approved CDTI project in July with an investment of over 300,000 euros. Innovation director, Arrate Olaiz, points out that two factors support this growth in R&D: "On the one hand, we are a larger company with more capabilities and a team, which allows us to intensify technological innovation; and, moreover, this year we have achieved full approval in Hazitek. We submitted six projects, and all of them were approved, which we couldn't achieve in previous years."

They will allocate over three million euros to six Hazitek projectsThe significance of these ongoing plans, as detailed by Arrate Olaiz, is that they are directly connected to the new market needs in areas such as "additive manufacturing with wire, controlled, flexible, and efficient machining of aeronautical materials, or the focus on high-value-added components in sectors like rail, which will capture strategic knowledge to diversify capabilities and customer sectors."

For instance, in wire-based additive manufacturing, a rapidly emerging technology, "we will develop three plans in collaboration with leading companies like Gestamp and the China Corporation of Railways." In the aerospace sector, under the leadership of Egile in 'Conflex,' Ibarmia will invest over one million euros to explore "new machine architectures that enhance performance and profitability."

AerospacePrecisely, Ibarmia's significant investment in the Haiztek 'Conflex,' with the participation of Egile Mechanics, Fagor Automation, Sariki, and Smart Process Management, aims to "design a new line of grinding machines that, while maintaining current precision and quality, increase productivity in the machining processes of NGV components and facilitate the use of standard grinding wheels." In additive manufacturing, Ibarmia has initiated a plan to position itself in wire technology after several years of progress in powder technology already present in its catalog. In 'Upscale,' led by Gestamp, the work will focus on integrating wire into robots and/or machines, with an initial industrial milestone expected for 2024. In the Hazitek 'Maqhia,' they will work on cases to validate Ibarmia's technology in collaboration with Eibar Precision Casting, Optimus 3D, ABC, or Delaser Global Solutions.

Lastly, in the same field, they have signed an agreement with Tecnalia China and the China Corporation of Railways, supported by CDTI, to create a hybrid process based on additive manufacturing, machining, and artificial vision for the repair of high-value-added railway components. "This solution will overcome the thermal deformation issues that occur with traditional welding systems."

Precision in MHThe innovation director also emphasizes Hazitek 'Accubask': "It's a project very much in the machine tool sector, which, after some time, has brought us together in a plan focused on precision, and it's a step forward born from an Elkartek. Ultimately, it's about integrating measurement into the machine as a standard process." The plan involves collaboration with Soraluce, Juaristi, Ona, Danobat, Zayer, Ibarmia, AFM, Fagor Automation, Maier, Gaindu, and Macarbox. In the competitive Hazitek and building on what was presented in 2022, Ibarmia will complete the 'Saturno' and 'Orkestra' projects. The first is aimed at creating a machining architecture for offshore components (flanges and bearings) of up to 12 meters in diameter, "although some customers are already inquiring about the possibility of reaching 14 meters"; while the second is focused on "advancing in the standardization of communication protocols to shorten lead times in automating various systems existing in the market based on customer demand."

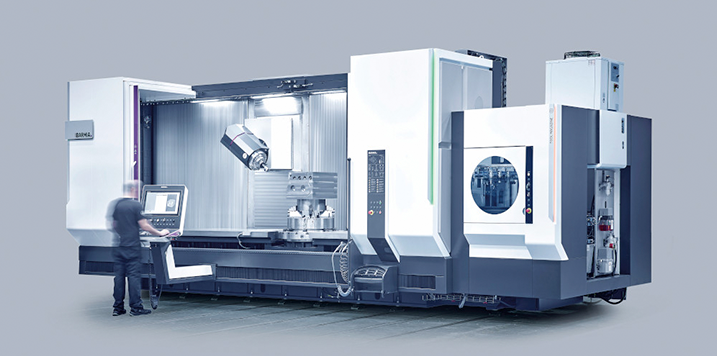

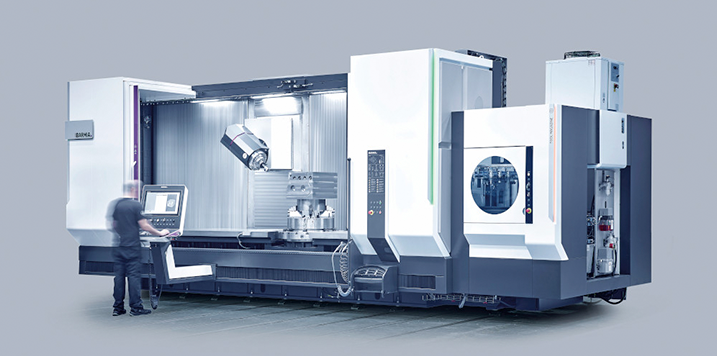

Ibarmia's innovative work has also shone at the EMO in Hannover, where they globally introduced the Generation 6 of their 'Z Series' machines: "Honestly, I believe it is the best ISO 50 mobile column machine in the market. There may be more economical solutions, but technically we have improved in key aspects. For example, while maintaining the same footprint, we have moved the tool storage from the column to the side, allowing for better utilization of workspace, tool loading and unloading while the machine operates, as well as improved dynamics."

Investments for 2024Lastly, as part of their industrial strengthening, they are finalizing the construction of a facility that will enhance assembly, storage, and logistics and will be in operation in the first half of 2024. Additionally, for the first half of 2024, they have already launched the construction of a 'Z Series' machine, up to 1600 mm, to internalize the production of components for their machines.

Source: Empresa XXI.

23 October, 2023Ibarmia Innovatek's innovative journey has gained momentum in the year it commemorates its 70th anniversary of establishment. The company will exceed three million euros in investment across six Hazitek 2023 projects in which it participates: four strategic projects (Accubask, Maqhia, Upscale, Conflex) and two competitive projects (Saturno and Orkestra), in addition to an approved CDTI project in July with an investment of over 300,000 euros. Innovation director, Arrate Olaiz, points out that two factors support this growth in R&D: "On the one hand, we are a larger company with more capabilities and a team, which allows us to intensify technological innovation; and, moreover, this year we have achieved full approval in Hazitek. We submitted six projects, and all of them were approved, which we couldn't achieve in previous years."

23 October, 2023Ibarmia Innovatek's innovative journey has gained momentum in the year it commemorates its 70th anniversary of establishment. The company will exceed three million euros in investment across six Hazitek 2023 projects in which it participates: four strategic projects (Accubask, Maqhia, Upscale, Conflex) and two competitive projects (Saturno and Orkestra), in addition to an approved CDTI project in July with an investment of over 300,000 euros. Innovation director, Arrate Olaiz, points out that two factors support this growth in R&D: "On the one hand, we are a larger company with more capabilities and a team, which allows us to intensify technological innovation; and, moreover, this year we have achieved full approval in Hazitek. We submitted six projects, and all of them were approved, which we couldn't achieve in previous years."