04 September, 2019

04 September, 2019Productivity, increased autonomy and improved accuracy. These are the axes of Juaristi's innovation strategy, which in recent months have resulted in the development of the new TH3-MT multifunction center, optimized for turning work with maximum reliability and the new universal heads ACD7 and ACD8, designed for 5 axes machining of maximum precision.

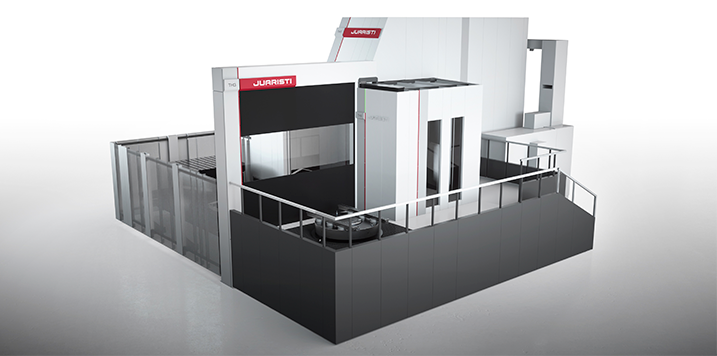

Juaristi, a company specialized in the design and manufacture of premium machining solutions, will use the 2019 EMO fair to present the most disruptive developments of the last year. On this occasion the company will show the benefits of the new TH3-MT multifunction center, its commitment to satisfy customers who demand a set capable of performing multiple machining techniques with high productivity and precise results, and the new range of 5-axis universal heads.

The new machining center is a development of the TH series, Juaristi´s 5-axis multifunction centers, which incorporates a lathe table and a special head with an optimized design for turning operations. The center includes an integral comprehensive automation package and has a completely renovated design to improve its ergonomics, extend its useful life and optimize chip and coolant management.

The TH3-MT maintains the main benefits of the solutions of the TH series: high dynamics (up to 40m / min of fast advance with accelerations of 3m / s²) and compatibility with highly advanced last generation tools. Thanks to the symmetrical design with a column-centered head and 4 guides (two front and two rear), it presents an unbeatable performance in terms of accuracy and offers a high cutting capacity.

The great novelty lies in the incorporation of a new special head for turning and a lathe table. The new head developed by Juaristi, dubbed ACD8, is a universal model that allows 5-axis machining and reaches speeds of up to 8,000rpm, with high power (60kW) and spindle torque (1,600Nm).

The lathe table that incorporates the machine will have a plate diameter of Ø1600 (optionally up to Ø2000) with a maximum speed of 400rpm and maximum piece capacity of 5ton in turning and 10ton in milling. The rotation speed reaches 400rpm.

The new machine incorporates multiple automation systems adaptable to customer requirements, among which a quick change matrix tool changer with a capacity of up to 200 tools and a FMS multipallet system stands out.

Finally, the TH3-MT has gone through a comprehensive redesign process, achieving a more stylized and ergonomic set. The new design achieves a more compact layout for better use of floor space. In addition, it optimizes the chip and coolant collection system, improving the autonomy of the solution and avoiding downtimes for manual cleaning.

Another of the improvements related to the design is the lining of the interior of the fairing in stainless steel, which protects the solution and extends the life of the machine. It emphasizes its good ergonomics, which allows a perfect control of the operations to the operator, as well as the careful disposition of the main components to facilitate its supervision and maintenance.

These new developments are framed within the C.A.S.T. (connectivity, automation, service and technology), concepts that govern JUARISTI's relationship with its customers. These areas will focus on the effort in innovation and development of the company in order to meet all customer needs with maximum versatility, improve companies through high-level services and build connected machines that cooperate efficiently and intelligently.

JUARISTI, experts in manufacturing milling and boring solutions and multifunction centers, has been a reference in the machine tool sector for more than 75 years. Its headquarters are located in Azkoitia (Gipuzkoa) and its product range covers all configurations of milling machines, boring machines and multifunction centers.

Subscribe to our newsletter. Just insert your e-mail and you will receive the latest news.