11 June, 2019

11 June, 2019The Guipuzcoan company Korta launches the Strategic Plan 2019-2021, in which they have set the challenge to grow and diversify their business. They have designed a series of actions with which they seek to increase sales at a rate of 10 percent per year.

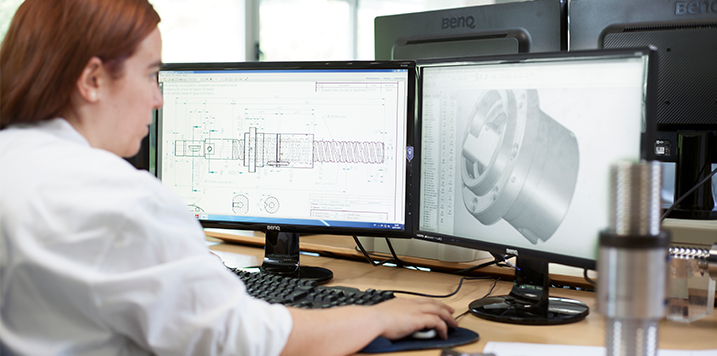

To achieve this objective, Korta will maintain the alignment of its capacity with the production of short and special series, which will affect the diversification of the target sectors of its products and will cover the entire range of diameters. In the commercial field, the machine tool will remain as its main sector, currently representing 50 percent of sales, but will continue to intensify the offer to sectors, such as, aeronautics-space, optics, electronics and high loads, such as presses and injectors. Another factor to energize the business is the commitment to the sensing of ball screws, marketed under the brand 'Korta + S'. With the support of the Gipuzkoa Provincial Council, SPRI and CDTI, and after three years of work in R+D, they have developed a preload and temperature measurement system, a project in which they have collaborated with the University of Mondragón and Ulma. The solution has already been presented at Biemh, AMB and Bimu fairs and it will be shown next September at the EMO in Hannover, date on which the process for the industrialization of the production of this equipment will have concluded.

The area of R+D also addresses a strategic project for the redefinition of the technical parameters of the spindle. This is based on achieving the confirmation of theoretical assumptions in empirical models, which will involve the generation of recirculation geometries of the balls that improve the performance of the machines in speed, lower noise, acceleration, product life, etc.

This type of work will give continuity to an activity that has given them success in the diversification towards aeronautics. In this case, they emphasize the development of an equipment to check cracks and burns of grinding, which was tackled together with Ceit. The system was very well received by customers in the sector and has opened the door for them to introduce their ball screws in projects for aeronautical actuation systems, which is facing an evolution of electromechanical-based hydraulic technologies, as well as solutions for satellites.

The technological, technical and commercial transformation of Korta will be based on an action plan to boost the industrial capacity of its plant in Zumaia, which will require an investment of around four million Euros until 2021. The main chapters will be the implementation of a new layout, in which the different manufacturing ranges will be reorganized and in which the assembly and control areas of the machining sector will be physically separated, in line with the differentiation they have already implemented with a room specifically created for aeronautical products.

The increase in manufacturing capacity will be faced with more efficient machinery and lower environmental impact, based on hard machining technologies, such as the integration of a pilot equipment developed by Danobat; miniaturized grinding, to promote new lines of business; or additive manufacturing, to be able to create new recirculation geometries.

The managers of Korta, finally, have set the commercial goal of maintaining 2018’s rate of sales and be at the border of 10 million Euros. Currently, manufacturing capacity is covered until September, with 70 percent of sales coming directly from abroad. The main destinations are companies from Italy, China, Germany, Austria and France.

Source: Empresa XXI

Subscribe to our newsletter. Just insert your e-mail and you will receive the latest news.