26 May, 2016

26 May, 2016In Laip S.A we design toolholders since 1957.

More and more the requirements in spindle rotations speeds, in final quality balancing requirements are becoming higher and higher.

These means that the toolholder and tool assembly group needs to be also at a very high degree of balance quality, for instance at this stage for HSK 63-A is a normal requirement to be in a quality degree of 2.5 G at the rotation speed of 25.000 rpm.

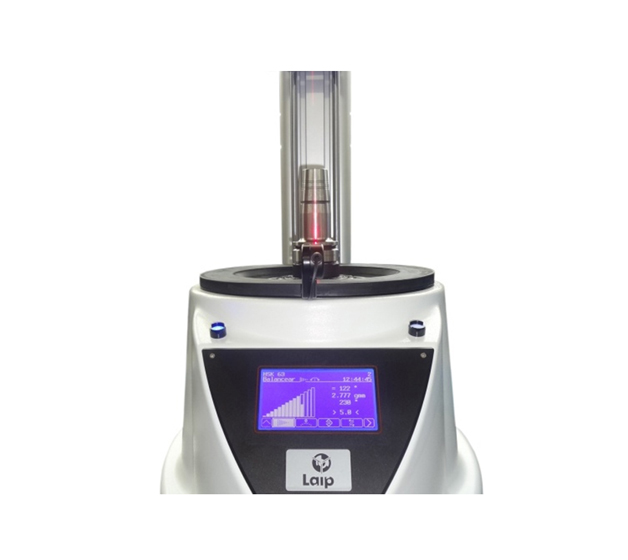

To face this requirement LAIP lace in the market 3 different versions of Balancing Machines:

First one, dedicated for very small toolholders, where it is necessary to achive quality degree of 2.5 G at the speed of 50.000 rpm, dedicated fo instance to:

HSK- 25, HSK-32, SK-30, BT-30.

The second one dedicated for a medium size toolholders systems like: HSK-32, HSK-40, HSK-50,HSK-63, SK-30,SK40,BT-40,BT-50.

And the last one is able to balance till HSK 100, BT 50, and SK 50.

All of the models allow equilibrating in one or 2 faces, depending the total length of the toolholder system.

The very friendly use software, precision, and portability makes from this machine type the perfect solution to install them in the tool room or even in the production line.

Subscribe to our newsletter. Just insert your e-mail and you will receive the latest news.