09 April, 2015

09 April, 2015Tivoly, taking advantage of the opportunity offered by the proximity of the final users to have first-hand knowledge of their needs, has developed the new version of Roll Taps, within its “FLASH CUT” high-performance tapping range.

Made of latest generation high-speed steel, with innovating geometry and optimised profile, the new Roll Tap becomes the tapping solution for materials with an elongation coefficient of at least 10% and tensile resistance of up to 1200 N/mm2, such as steel, stainless steel, pure titanium, aluminium, copper, long shaving brass, etc. Any material, which, when drilled, generates long, continuous shavings is a good candidate to be tapped by the new FLASH CUT ROLL TAP.

After many tests at its R&D&I centre, Tivoly has managed to improve the performance of its new Roll Tap thanks to a new design that increases the flow speed of the material of the part to be worked, as well as a decrease in the heat generated.

The new geometry allows the fibres of the material to move better, reducing friction between the tap and the part, decreasing wear by adherence and increasing the working life of the tool. The different performance tests conducted have shown that the torque is reduced by more than 15% and the number of threaded holes is doubled.

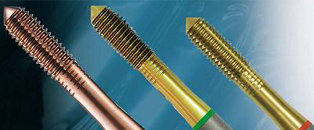

The different coatings available permit a personalised solution for each material to be machined.

The new range comes with and without lubrication grooves and it is manufactured on demand with inner lubrication holes.

In short, the excellent design of the new Roll Tap offers us ecological tapping with great advantages: Very resistant taps, no shavings, longer working life of the tool and excellent tap quality.

Subscribe to our newsletter. Just insert your e-mail and you will receive the latest news.