03 June, 2022

03 June, 2022The package of innovative solutions for articulated cobots and robots highly anticipated by development engineers in the industrial sector has finally arrived, and Schaeffler presented it at the Hannover Messe. The manufacturing industry needs lightweight robots that are highly dynamic and precise. At the same time, applications in the food industry and medical engineering also require them to be highly sensitive, while the focus of medium-sized companies revolves around flexible and simple use.

Ralf Moseberg, head of the Industrial Automation business area of Schaeffler, has the following to say about the state of the industry: “These ambitious goals cannot be achieved with just one component. We have taken this challenge head on, developing new main bearings, engines, gearboxes and a fully integrated robot and cobot sensor system. Our solutions package will enable cobots to function 50% faster, while carrying loads up to 30% heavier, and our innovative precision gearbox concept with integrated sensor system will provide the necessary sensitivity. This will allow us to explore other areas of application”.

Cobots that combine great dynamism and sensitivity are capable of much more flexible uses: they can offer anything from collaborative applications to classic industrial robot applications, which means that not only can systems can be made more profitable much faster and productivity increased considerably, but also demand for cobots is stimulated. In this context, Ralf Moseberg sees associated benefits for Schaeffler: “We have everything that’s needed to meet the future demand for lightweight robot system components, including the production capacity and the necessary quality management for medium to large scale production. Robots are a field with considerable growth potential for Schaeffler”.

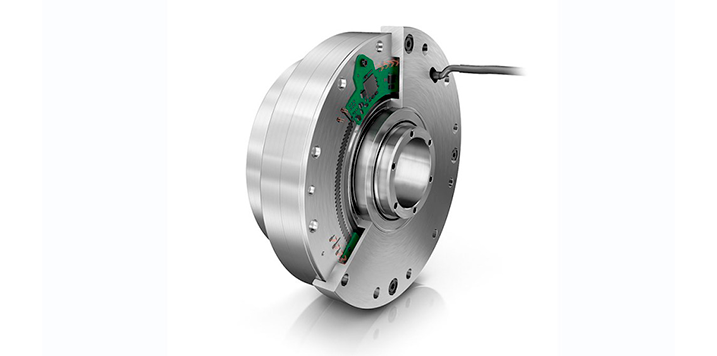

Schaeffler will also present a range of PSC series precision planetary gearboxes for industrial robots at the Hannover Messe. These gearboxes feature a torsional clearance ten times lower and a useful life three times longer than the market standard. They also feature a wear compensation system which keeps the torsional clearance extremely low on a consistent basis. These major advancements are a rare occurrence in mechanical engineering and provide an opportunity for industrial robots to overcome previous obstacles.

This, in turn, enables Schaeffler to offer this year precision gearboxes and precision planetary gearboxes for articulated robots, in all axes and loads, ranging from just a few kilograms to over 100 kg.

Subscribe to our newsletter. Just insert your e-mail and you will receive the latest news.