27 April, 2023

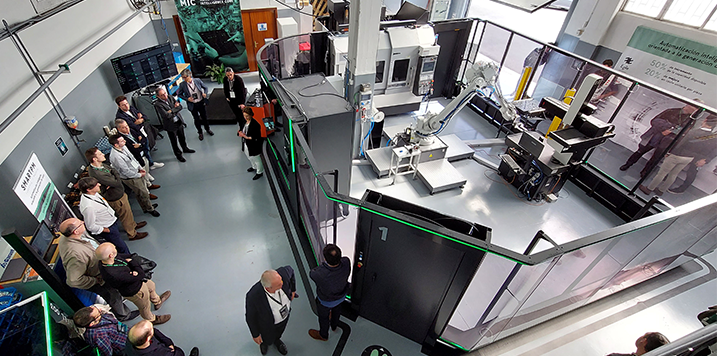

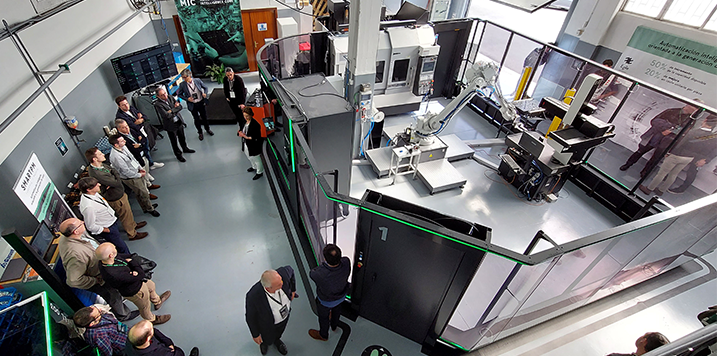

27 April, 2023The event was held on March 30 at its facilities in Elgoibar (Gipuzkoa), where the doors of the FACTORY Lab remained open all day. Professionals from the industrial sector, such as operators, engineering or industrial management managers, attended the morning or afternoon sessions organized by SMARTPM.

After receiving the companies and collaborators in attendance, there was a short introduction to the so-called smart factory, sharing the vision of what a flexible factory is today, proposing a future that is already present with technologies and products available on the market.

The professionals from SMARTPM, MAQcenter, Hexagon, ZOLLER, ABB and Hoffmann Group, shared a very convergent vision regarding the importance of digitizing what we manufacture and the importance of integrating that layer of data with what happens in the workshop. And they did not forget one more key element: process management.

José Castellanos, general director of SMARTPM, pointed out the importance of avoiding technological silos in factories. "The collaborators who have participated in OPEN HOUSE have first-rate tools and products, and the MIC platform plays a key role. They are short, with multiple references and with a lot of capacity for continuous improvement."

He also referred to smart integration. "In other words, that this important data that we are capturing is used for something really useful, such as that the cell and the processes function more and more autonomously."

Live and direct management of 5 workflows of different referencesWith their eyes on the manufacturing cell and control panel, the SMARTPM team put the automated process into action.

During the demonstration, 5 different references were manufactured with short series, even unitary, and each of them with its different processes, programs, tools and even different tools.

While the center was milling, the robot was polishing another part and the 3D was busy inspecting another part. Simultaneously, the warehouse managed a buffer of parts already prepared with a preset to feed the machining. Once the machining was finished and while the inspection was being carried out, the robot carried out third operations. At the same time, new references were registered, managing alarms and even incorporating material from outside the warehouse.

The whole process worked correctly, autonomously and intelligently. Gathered around the cell, attendees saw how the MIC system is capable of managing multi-piece and multi-reference processes with autonomy and fluency.

Likewise, the monitoring was constant, displaying on the control panel the KPIs generated, the quality of the parts (seeing the reports of the Hexagon inspection solution on the screen, in this case). The workflow developed as planned in terms of quality and time.

Bring the concept of Smart Industry down to earthHolding these conferences is essential to bring the concept of Intelligent Industry closer to companies.

“At SMARTPM we are developing a solution that constitutes a new product category. There are different solutions for data capture, program management, and even specific optimization of machining processes. However, there was no solution that would allow orchestrating the operation of different assets with the flexibility that is demanded today in the market”, comments José.

In short, the demonstration at the FACTORY Lab made it possible to show the impact that the MIC platform can have on the processes of each company, improving the productivity and flexibility of the plants.

27 April, 2023The event was held on March 30 at its facilities in Elgoibar (Gipuzkoa), where the doors of the FACTORY Lab remained open all day. Professionals from the industrial sector, such as operators, engineering or industrial management managers, attended the morning or afternoon sessions organized by SMARTPM.

27 April, 2023The event was held on March 30 at its facilities in Elgoibar (Gipuzkoa), where the doors of the FACTORY Lab remained open all day. Professionals from the industrial sector, such as operators, engineering or industrial management managers, attended the morning or afternoon sessions organized by SMARTPM.