01 July, 2020

01 July, 2020Machining errors may have many causes, some of them related to features associated with the design, with the kinematics, the assembly, etc. Here Fagor Automation’s latest piece “Easy Volumetric Compensation” allows fixing machining errors.

The best way to solve some of these errors is by properly designing the machine. However, this is not always possible or not economically viable.

On the other hand, in medium or large sized machines, increasing rigidity may be impossible beyond a certain limit, or can have an unacceptable cost.

This is why classic error compensation tools need to be complemented with more advanced tools that adapt to different machine designs, even with particular kinematics.

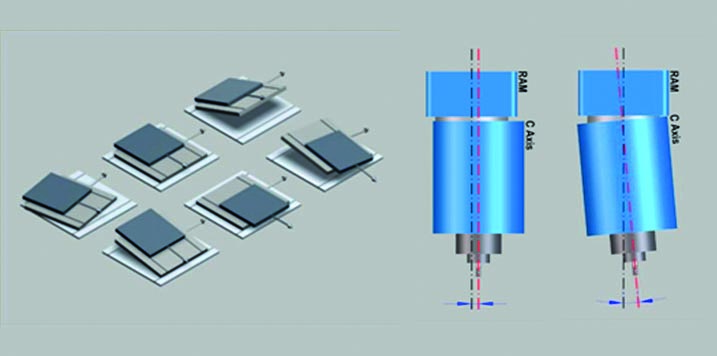

A few years ago, Fagor Automation launched Volumetric Compensation as a response to that need. Using measurements made by specialized companies, up to 21 compensation tables were generated, which the CNC managed simultaneously to obtain high quality machining.

With the recently launched “Easy Volumetric Compensation”, it is enough to define 25 control points per axis; therefore, it is much faster to calibrate and integrate the points into the CNC.

This greatly improves the accuracy of the machine and is more affordable because it avoids the need to hire external companies to take the measurements. Without reaching the accuracy levels of the standard Volumetric Compensation, very relevant and valid improvements in accuracy are achieved for most machines.

Subscribe to our newsletter. Just insert your e-mail and you will receive the latest news.