19 July, 2023

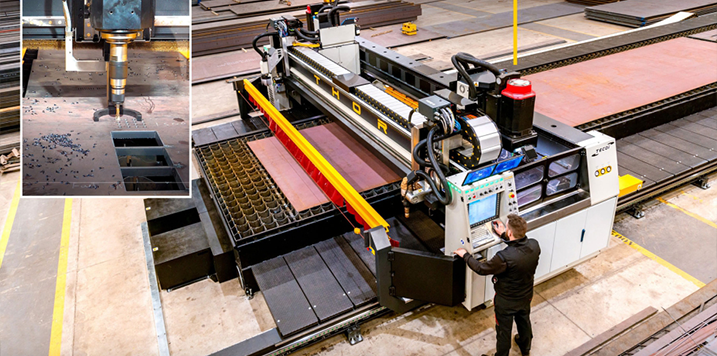

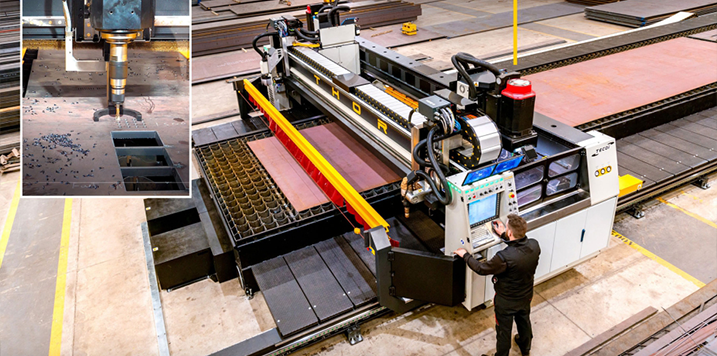

19 July, 2023Tecoi has developed a revolutionary solution for the metal production sector with its new sheet metal processing station called Thor. Designed specifically for steel mills and service centers, this versatile machine is designed to help companies expand their customer base.

Known as the Tecoi Hyper Operative Range, Thor combines plasma cutting heads at its front, including the exclusive Bevel ARC 5-axis beveling system, with two high-performance multi-tool machining heads at its center area. This takes the concept of versatility to a new level.

With a power of 45 kW S3 and the capacity to use more than 32 different tools, these heads allow to work independently and simultaneously in thicknesses of up to 200 millimeters. This gives the Thor machine a machining capacity never seen before in a sheet metal cutting machine. In addition, the change of tools is automatic, which ensures high productivity rates.

The versatility of the Thor machine is extended with the option of incorporating up to 12 flame cutting heads, which allows it to handle any thickness according to production needs. In addition, this machine can be adapted to the specific needs of each client by incorporating an automatic tube lathe and state-of-the-art sheet metal marking and identification systems. As an additional feature, Thor offers the possibility of incorporating Vibratec, an automatic slag extraction system patented by Tecoi.

With a robust double beam design, Thor is prepared to withstand high workloads, even in continuous production, which has made it one of the most requested models in the sheet metal transformation market.

Source: Interempresas.

19 July, 2023Tecoi has developed a revolutionary solution for the metal production sector with its new sheet metal processing station called Thor. Designed specifically for steel mills and service centers, this versatile machine is designed to help companies expand their customer base.

19 July, 2023Tecoi has developed a revolutionary solution for the metal production sector with its new sheet metal processing station called Thor. Designed specifically for steel mills and service centers, this versatile machine is designed to help companies expand their customer base.