13 December, 2016

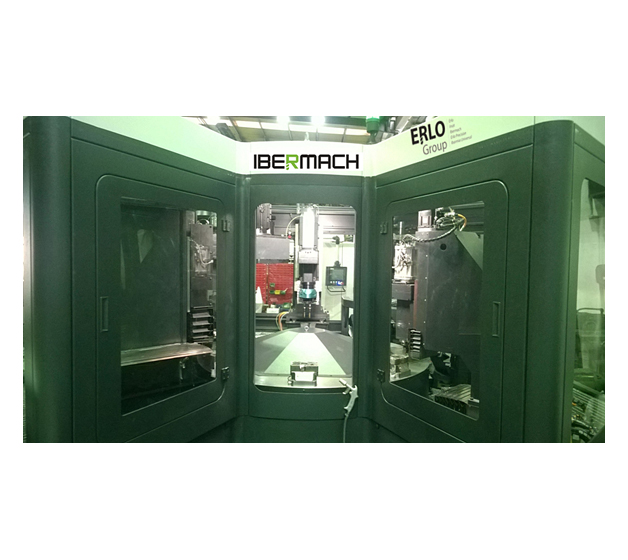

13 December, 2016The Erlo Group has presented its new machining transfer designed by IBERMACH to carry out different operations such as drilling, threading, chamfering and milling of several areas of the engine support for Renault.

This transfer is comprised of eight workstations:

- Loading and unloading parts by robot

- Milling flat side with 125 diameter cutter

- Drilling a 7.4 diameter hole and chamfering the three holes of the same size

- Boring and chamfering with 42 diameter

- M8 triple threading

- Plane lower area of mounting hole

- Milling and chamfering keyway

- Milling entire contour

It also has a thread verification system with three sensors that detect the presence or not of the thread. Then, the robot is responsible for separating the good parts from the faulty ones.

Subscribe to our newsletter. Just insert your e-mail and you will receive the latest news.