05 November, 2020

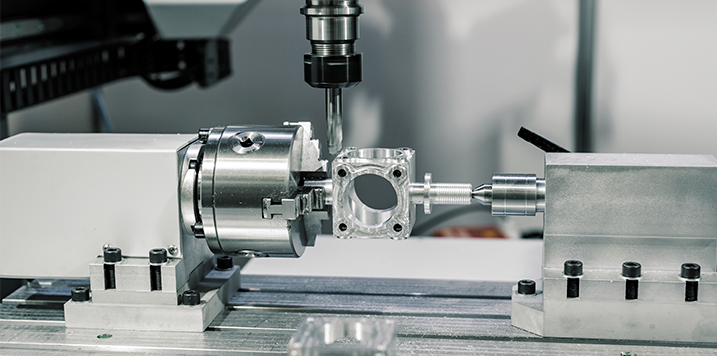

05 November, 2020On 24 September, ZAYER presented the results of the first milestone of the MEDECO project, headed by this milling machine and machining centre manufacturer, which aims to find solutions to the needs of sectors such as the aeronautical, oil and gas and wind power industries, which are demanding improvements in their competitiveness to avoid having to move their production to countries in the Asian Pacific.

Notable among their first results are the implementation of fingerprinting technology for linear and rotary machine axes. A series of KPIs have been obtained without external means and via simple and automatic cycles to perform a quick diagnosis on the status of the machine. An increase in the multitasking capabilities of the machine have been obtained by the development of non-conventional turning cycles that are easy to parameterise, as well as the implementation of a specific swarf-breaking strategy for ductile steel turning.

This initiative is financed by the Centre for Industrial Technological Development (CDTI) and the Ministry of Science and Innovation.

Subscribe to our newsletter. Just insert your e-mail and you will receive the latest news.